Does a foldable design sacrifice insulation? Unveiling the synergy between cardboard box structure and insulation materials.

Here's a question that gives anyone in perishable logistics pause: If a cold chain carton is foldable, does it offer less insulation? It's a perfectly fair concern. For a long time, the industry has viewed rigid, sturdy containers—like thick foam coolers—as the undisputed champions of thermal protection. The very idea of a box that collapses seems, at first glance, to contradict the core mission of maintaining a consistent, safe temperature for sensitive goods. But what if modern packaging has turned this assumption on its head? Today's engineering advancements reveal that foldability is not a compromise; it's a sophisticated feature that can work in powerful synergy with insulation. Let's explore how a well-designed foldable carton can not only match but potentially enhance cold chain performance.

Debunking the Myth: Foldability Versus Structural Integrity

The concern often stems from a simple association: if something bends, it must be weak. In the realm of engineered corrugated cardboard, this is a misconception. A box's strength and insulating properties come from a combination of its material composition and its intentional structural design. A foldable design is primarily about precision—specifically, the accuracy of its crease lines and the strategic placement of scores and cuts. This allows the box to collapse neatly for storage without damaging the core panels that form its insulated cavity. When assembled, these panels lock into place, often reinforced with interlocking flaps or tabs, creating a rigid structure that is just as robust as a non-collapsible counterpart during use. The fold is a feature for logistics efficiency, not a flaw in its thermal defense.

The True Hero: Multi-Layer Insulation Construction

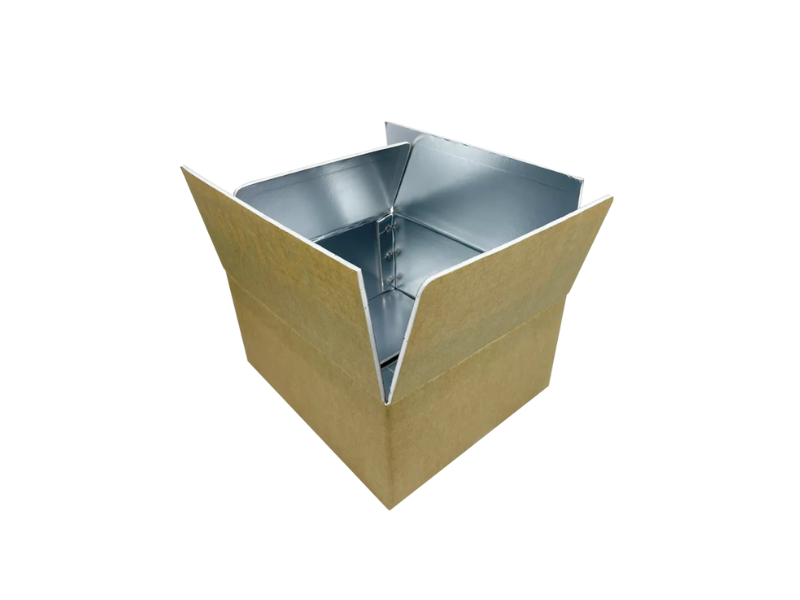

Insulation in a high-performance foldable cold chain carton is not merely about the cardboard itself. It is achieved through an integrated, multi-material, multi-layer system. Think of it like a premium winter jacket. The outer corrugated layer acts as the durable, protective shell. The real thermal performance comes from the inner layers.

A typical advanced design incorporates the following:

-

Exterior Layer: High-grade, moisture-resistant corrugated board provides durability and essential stacking strength.

-

Barrier Layer: A thin film or coating acts as a vapor barrier, preventing external humidity from degrading the insulation and stopping internal dry air from escaping.

-

Core Insulation Layer: This is the critical component, responsible for the thermal resistance (R-value). It may consist of advanced materials like molded fiber cushioning, laminated foam sheets, or bio-based insulating pads.

-

Inner Liner: A smooth, food-safe surface protects the product and is easy to clean.

In a competently designed foldable carton, these layers are laminated or integrated so the insulation core can flex at the pre-determined folds without cracking, delaminating, or losing its insulating properties. The fold is engineered into the entire composite system.

Engineering Synergy: Where Structure Meets Material

The most effective designs are born from co-engineering the cardboard structure with the insulation material. The flutes within the corrugated board (the wavy inner layer) do more than provide strength; they create countless tiny pockets of trapped air, which is a natural insulator. The carton's architecture is optimized to maximize this effect. Furthermore, once assembled, the rigid panels protect the softer insulation core from compression, which is the enemy of effectiveness—flattened materials lose their air pockets and thus their insulating power. A quality foldable carton uses its structural walls to bear stacking loads, shielding the insulation and preserving its loft and R-value throughout the shipping journey.

Benefits Beyond Insulation: The Systemic Advantage

Solving the foldability-insulation equation unlocks systemic advantages that traditional rigid coolers cannot offer:

-

Space Efficiency: Empty cartons can be collapsed, reclaiming over 80% of the storage and transportation space used by rigid boxes, dramatically cutting logistics costs.

-

Waste Reduction: A durable, multi-trip foldable system replaces countless single-use foam coolers, supporting the sustainability and FSC-certified sourcing goals upheld by leading manufacturers.

-

Consistent Performance: Standardized, professionally designed cartons ensure identical thermal protection for every shipment, removing the variables introduced by makeshift packaging solutions.

-

Workflow Improvement: Easy assembly and flat storage reduce labor time and warehouse congestion.

The Critical Role of Professional Design and Testing

This level of integration is not accidental. It requires a partnership with a packaging specialist possessing deep expertise in structural design and material science. A true partner like Zhuoyue looks beyond mere printing. Their design team considers the specific thermal needs of your product (frozen, chilled, etc.), transit duration, and external conditions. They then prototype, testing combinations of board grade, flute profile, insulation core, and fold patterns to meet precise performance benchmarks—a process that may include thermal chamber testing to validate hold times. Their end-to-end control over the process, from certified raw materials to final production, ensures a level of quality and consistency that generic or DIY approaches cannot achieve.

Conclusion: A New Paradigm for Cold Chain Packaging

So, does a foldable design mean sacrificing insulation? The clear answer is no—provided the carton is purposefully engineered from inception with insulation as a primary goal. The perceived conflict vanishes when you understand that modern foldable cold chain cartons are advanced composite systems. The cardboard provides an intelligent, space-saving, and robust structure, while the integrated materials deliver the thermal barrier. Together, they create a solution greater than the sum of its parts: reliable temperature protection paired with revolutionary logistical efficiency. The choice is no longer between strength and smart storage; it's about collaborating with experts who have mastered the synergy of both.