Როგორ შეიძლება საცივ ჯაჭვთან დაკავშირებული საწყობის ეფექტიანობის 20%-ით გაუმჯობესება სტანდარტიზებული დიზაინის გამოყენებით?

Ნებისმიერი ადამიანი, ვინც მუშაობს გასაფუჭებელ საქონელთან, იცის, რომ დაკარგული სივრცე მთავარი პრობლემაა. უნდა გადაადგილდეს ყინული ზღვის პროდუქტები, სურსათი თუ ca ყინული, თქვენი შეფუთვის არჩევანი პირდაპირ აისახება ექსპლუატაციის რთულებზე და ხარჯებზე. ტრადიციული მყარი ცივი ჯაჭვის კონტეინერები ხშირად ქმნიან მდგრად პრობლემას გამოუყენებელი სივრცის შესახებ, რაც ავსებს თქვენი ტვირთის ავტომობილების და საწყობის მოცულობას. რა მოხდება, თუ თქვენ შეძლებთ უკეთესად გაკეთოთ? არსებობს გამჭვირვალე მიდგომა - ერთი, რომელიც ეფექტიანობას ამაღლებს სტანდარტიზებული, მორგებადი ცივი ჯაჭვის ყუთებით. ეს არ არის უბრალოდ უკეთესი ყუთის შესახებ; ეს არის თქვენი მთელი სამუშაო პროცესის ხელახლა დაგეგმვა გაზომვადი ეკონომიისთვის. მოდით გამოვიკვლიოთ, თუ როგორ შეიძლება კარგად შემუშავებულმა მორგებადმა ამოხსნამ რეალურად მიაღწიოს 20%-იან გაუმჯობესებას ტვირთის დატვირთვაში და საწყობში.

Ძირეული პრობლემა: არასტანდარტული შეფუთვის არაეფექტიანობა

Სწორი ამოხსნის პოვნისთვის ჯერ უნდა გავიგოთ გამოწვევა. ბევრი ოპერაცია დამოკიდებულია სხვადასხვა ზომის გაგრილებლებზე, ქსოვილის ყუთებზე და არაშეკვეცად მარილით დაფარულ ყუთებზე. მიუხედავად იმისა, რომ ეს ტარები იცავს პროდუქებს სავსე მდგომარეობაში, ცარიელ მდგომარეობაში ისინი ხდებიან პრობლემა. ისინი იკავებენ იგივე მოცულობას სავსე ან ცარიელი მდგომარეობის შემთხვევაში, რაც ქმნის იმას, რასაც ეწოდება „მკვდარი სივრცე“. ეს მკვდარი სივრცე ძვირი ჯდება: სატვირთო მანქანები ათავისუფლებენ საწვავს ჰაერის ტრანსპორტირებით განაწილების ცენტრებში, ხოლო საწყობები თავისუფალ ადგილს მიუძღვნიან ცარიელი ტარების შესანახად. ეს არეფექტიანობა პირდაპირ ამცირებს მოგების მარჟებს. სტანდარტიზებული, შეკვეცადი დიზაინი ამ პრობლემას პირისპირ ეყება შეფუთვის ცხოვრების ციკლის გადაფიქრებით.

Სტანდარტიზაციის ძალა

Უფრო მაღალი ეფექტიანობისკენ პირველი ნაბიჯი განზომილებითი ერთგვაროვნებაა. ოცი პროდუქისთვის ოცი სხვადასხვა ყუთის გამოყენების ნაცვლად, ოპტიმიზებული სისტემა ეფუძნება ზომების შეზღუდულ ნაკრებს, რომლებიც ერთმანეთის ჯერადია. წარმოიდგინეთ თქვენი საწყობის პალეტები, სატვირთო მანქანების ჩამოსადგენი ადგილები და თაღები როგორც ბადე. სტანდარტული ყუთები შექმნილია ისე, რომ იდეალურად მოე fits ამ ბადეს, როგორც ერთმანეთს შემომხვეული თავსატევის ნაწილები. ძირეული ყუთის ზომა შეიძლება იყოს შემუშავებული ისე, რომ სტანდარტულ პალეტზე თითო ფენაზე მოთავსდეს ოთხი ერთეული, ხოლო ნახევარ- და მეოთხედ-ზომის ვარიანტები გამოყენებული იქნეს სივრცის შესავსებლად და შერეული ტვირთის ოპტიმიზაციისთვის. ეს აღმოფხვრის პალეტებზე არასასურველ ცარიელ სივრცეებს და უზრუნველყოფს ყოველი ტვირთისთვის მუდმივ, მაქსიმალურ ტვირთს. ლოგისტიკის დაგეგმვისთვის ეს ნიშნავს პროგნოზირებად ტევადობას, უფრო მარტივ მარშრუტის დაგეგმვას და ნაკლებ დროს ტვირთის დატვირთვის დროს ხელით შესწორებისთვის.

Თამაშის შემცვლელი: სივრცის დასაბრუნებლად საშეკრი დიზაინი

Აქ ხდება ნამდვილი გარდაქმნა. შესაბამისად შემუშავებულ საცივ ჯაჭვზე ორიენტირებულ საწყობ ყუთზე შეკუმშვისას შეიძლება შემცირდეს მისი საწყობი ფართობი 80%-მდე. მიტანის შემდეგ, ნაგულისხმევად მუშაობისა და ადგილის დიდი ცარიელი ყუთების დასაგროვებლად, თქვენი გუნდი სწრაფად შეძლებს მათ გაშლას და გადაფარდებას. მაგალითად, 50 შეკუმშული ყუთი შეიძლება დაიკავოს მხოლოდ 10 შეკრული ყუთის ადგილი. ეს მomentალურად გაათავისუფლებს მნიშვნელოვან საწყობს. უფრო მნიშვნელოვანი კი ისაა, რომ ეს ახდენს რევოლუციას უკან დაბრუნების ლოგისტიკაში: სატვირთო მანქანები შეძლებენ ასობით გაშლილი ყუთის დაბრუნებას ერთი მოძრაობით, რაც აღმოფხვრის ხარჯობრივ ცარიელ ან დაუტვირთავ უკან დაბრუნების მოძრაობებს. ამ სივრცის დაბრუნება არის უმარტივესი გზა მნიშვნელოვანი მოგების მისაღებად როგორც საწყობებში, ასევე ტრანსპორტირების ეფექტიანობაში.

Სტრუქტურული მთლიანობისა და პროდუქტის დაცვის უზრუნველყოფა

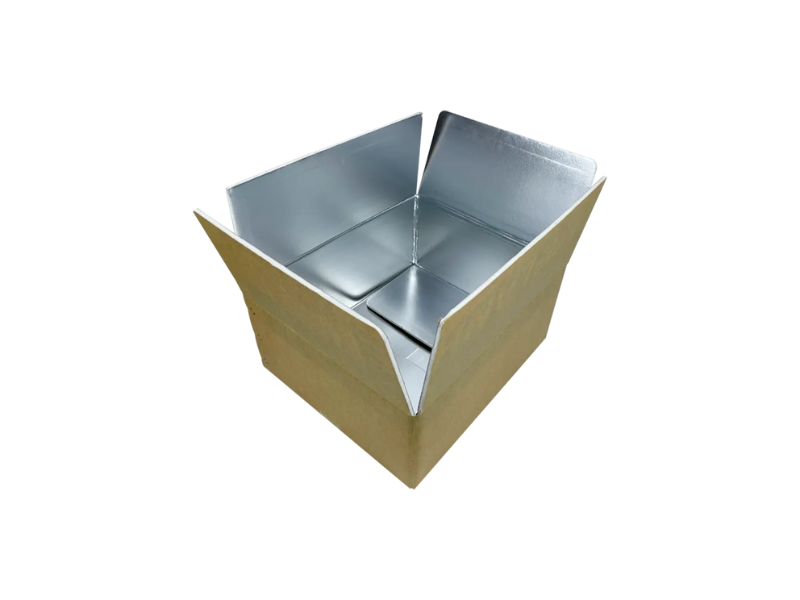

Შესაძლოა, ზოგი მოიფიქროს, რომ „საწოლი“ ნიშნავს „ნაკლებად მდგრადს“, მაგრამ პროფესიონალურად შემუშავებული ამოხსნების შემთხვევაში ეს ასე არ არის. გამოცდილი წარმოებლები უპირატესობას ანიჭებენ მდგრადობას და მასალათა მეცნიერებას უმაღლესი ხარისხის სტრუქტურულ დიზაინთან აერთიანებენ. Zhuoyue-ში ყუთების ინჟინერიის ათობით წლის გამოცდილება განაპირობებს სითბომედეგი გოფროვანი ფილის, საკვებისთვის უსაფრთხო შიდა ზედაპირების და განსაკუთრებული საფარის გამოყენებას ცივი ჯაჭვის შესანარჩუნებლად. ზუსტად დანიშნული ნაღმები და საიმედო ჩაკეტვის ელემენტები საშუალებას აძლევს ყუთს მრავალჯერადად შეიკრიბოს და გაშლილ მდგომარეობაში იმყოფებოდეს მთლიანობის დაკარგვის გარეშე. შეკრებული მდგომარეობისას ეს ყუთები უზრუნველყოფს საიმედო გადახურვის მდგრადობას და პროდუქების დაცულობას. საბოლოოდ, კარგად შექმნილი საწოლი კონსტრუქცია იძლევა საიმედო გაყინვის ყუთი მიღწევას, ამავდროულად უზრუნველყოფს უპარალელო სივრცის ეკონომიას — ეს არის გაუმჯობესება, არა კომპრომისი.

Სამუშაო პროცესის ოპტიმიზაცია და შრომის ხარჯების შემცირება

Ეფექტურობა არ მოიცავს მხოლოდ კუბურ სივრცეს — ის ასევე დროსა და მოძრაობას შეეხება. სტანდარტიზებული, გადასაღები ყუთები პროცესებს გაამარტივებს ყველა ეტაპზე. საწყობის თანამშრომლებს ნაკლები დრო სჭირდებათ სწორი ზომის ყუთის მოსაძებნად და საერთო დიზაინის დახმარებით ასაშენად ის სწრაფად და ინტუიციურად ხდება. ოპერაციებისთვის, რომლებიც ავტომატიზაციას იყენებენ, საწარმოს ხაზები შეიძლება გადაიტრიალოს ერთი ტიპის ყუთზე, რაც მნიშვნელოვნად აჩქარებს დაფასოებას. ტვირთის ჩატვირთვა უფრო სწრაფი და უფრო უსაფრთხოა, რადგან ერთგვაროვანი ყუთები ქმნიან მდგრად, ურთიერთდაბლოკილ პალეტებს, რომლებიც გადატვირთვის დროს ნაკლებად არის გადაადგილების გარდაცვლილი. მიღების მხარეს, გაშლა და ბრტყელი საწყობში შენახვა ამცირებს მუშაობის დროს. ეს დროის დაზოგვა მთელ მიწოდების ჯაჭვში მნიშვნელოვნად უწევს წვლილს 20%-ით უფრო მეტი ეფექტურობის მიღწევაში.

Ინტეგრაცია ავტომატიზაციასა და განათლებულ საწვავებში

Ლოგისტიკის მომავალი increasingly ავტომატიზებულია. ასეთი სისტემები, როგორიცაა ავტომატიზებული შენახვა და აღდგენა (AS/RS), რობოტიზებული პიკერები და სატრანსპორტო ხაზები მუდმივობაზე არის დამოკიდებული. სტანდარტიზებული ყუთები მანქანათა მეგობრულია — მათი წინასწარ განსაზღვრული გაბარიტები და მახასიათებლები ავტომატიზებულ მოწყობილობებს უზრუნველყოფს მათ საიმედო მოვლენით. საჭრელი კონსტრუქციები ამ უპირატესობას ცარიელი კონტეინერების მოვლენასაც ვრცელდება, რაც ავტომატიზაციის სრულ შესაძლებლობას უზრუნველყოფს დაბრუნების და შენახვის პროცესში. ასეთ შეფუთვის სისტემაში ინვესტიციები თქვენი ოპერაციის მომავლისთვის უზრუნველყოფს, რაც საშუალებას გაძლევთ მასშტაბირებად იყოთ ტექნოლოგიებთან ერთად, არა იმით, რომ შეჩერდეთ კონტეინერების არაწესრიგიერი ნარევით.

Პროფესიონალური დიზაინ-პარტნიორობის მნიშვნელობა

Ინტეგრირებული ეფექტიანობის ამ დონის მიღწევა არ წარმოადგენს თვითშეკრებად ამოცანას. ეს მოითხოვს პაკეტირების სპეციალისტთან თანამშრომლობას, რომელიც მიღებული აქვს მხოლოდ მარტივი ბეჭდვის ზღვარი. ჭეშმარიტი პარტნიორი ანალიზის დაქვემდებარებს თქვენი პროდუქციის მთელ ასორტიმენტს, გაყიდვების არხებს და ტრანსპორტირების მარშრუტებს. ისინი აკონტროლებენ, თუ როგორ შეინახება ყუთები თქვენს საწარმოში, როგორ დაელოდებიან საწარმოში და როგორ მოხდება მათი მომსახურება დანიშნულების ადგილას. პროფესიონალური დიზაინ-გუნდების მეშვეობით და წარმოების მკაცრი კონტროლით — FSC-სერთიფიცირებული ნედლეულის შეძენიდან დაწყებული საბოლოო პროდუქტამდე — კომპანიები, როგორიცაა Zhuoyue, შეძლებენ შექმნან გადაღებადი ყუთების ინდივიდუალური სისტემა, რომელიც უმეტესად შეესაბამება თქვენს ოპერაციებს. მათი გამოცდილება უზრუნველყოფს დიზაინის სტრუქტურულად მდგრადობას, დამცავ მახასიათებლებს და სტრატეგიულად გამოფინებულ დიზაინს, რომელიც სივრცესა და დროს ზოგავს.

Დასკვნა: სტრატეგიული ინვესტიცია

Სტანდარტიზებული, შეკეცადი ცივი ჯაჭვის ყუთების სისტემის განხორციელება სტრატეგიული ოპერაციული ინვესტიცია. ინტელექტუალურ დიზაინზე საწყისი ფოკუსირება მოგვცემს მოგებას მაქსიმალური ტვირთის მოცულობის, ცარიელი ყუთების საცავის სივრცის დრამატულად შემცირებული მოთხოვნილების, დაბრუნების ტრანსპორტირების დაბალი ხარჯების, შრომის მოთხოვნილების შემცირების და ავტომატიზაციასთან უფრო გლუვი ინტეგრაციის სახით. ეს ფაქტორები ერთად აერთიანებული კონსერვატიულ 20%-იან გაუმჯობესებას უზრუნველყოფს ტვირთის დატვირთვაში და საწყობებში, რაც შესაძლებელი ხდება. ეს ნიშნავს ინტელექტუალურად მუშაობას, ნებისმიერი სახის ნაგავის შემცირებას და შეფუთვის გადაქცევას ხარჯების ცენტრიდან კონკურენტული უპირატესობის წყაროდ.