What Insulation Layer of Cold Chain Boxes Is Suitable for 48-hour Fresh Transportation?

Shipping summer is an experience every business should go through. The 48-Hour Challenge is a company that specializes in transporting perishable goods and making sure it arrives in perfect condition. With every shipment, the company is entrusted to deliver sensitive goods (food, vaccine, fillets) in less than 48 hours. Their goal is to take the stress of shipping sensitive. This is a future shipping company that is improving the world of shipping frozen goods and is a company you can trust to deliver every time.

The Science Of Effective Insulation

The insulating core is most important to each reliable Cold Chain Box. This is because for 48-hour trips, some foams would not be suitable. It comes down to a material's thermal resistance (R-value), density, durability, and environmental footprint.

Expanded Polystyrene (EPS) is a cheap and common selection. It’s lightweight, and for some trips, it provides decent insulation. For trips of even moderate temperature sensitivity, standard EPS 48-hour trips eventually run into their insulation limitations. EPS is more prone to compression and may not be to provide the constant thermal barrier needed in extreme conditions.

The next step up is Polyurethane (PU) foam, which is injected in a liquid form. It expands and cures in place creating a seamless layer of insulation. PU is better in performance, and comes with a more superior R-value per thickness compared to EPS. This results in better insulation in a thinner wall profile and keeps the box efficient. It also resists moisture, and this in turn gives extra strength to the box so it doesn't crush when stacked during transport.

In high-value shipments, VIPs (Vacuum Insulation Panels) are the top passive insulation systems. In defending heat transfer through film, the vacuum seal cuts down on insulation thickness. VIPs' thinness, high insulation value, and lightweight materials contribute to their high R value. This is especially beneficial to high-resource shipments (e.g. produce, pharmaceuticals) with limited compact volumes. Their decisions center around cost and the fragility of the vacuum seal.

Modern combined systems are on the cutting edge of research. These reflect off Radiant barriers to remove heat. When combined with the latest foams, heat is radiated away and conduction is minimized. These systems are designed to stop conduction, resonance, and even convection in their tracks. They are dialed in for extreme environments and long times.

Beyond the Layer: A Systems Approach

A single insulative layer does not assure performance. The performance of each integrated cold chain box system relies on the others.

Together all components integrated to perform seamlessly to create a top of the line cold chain box.

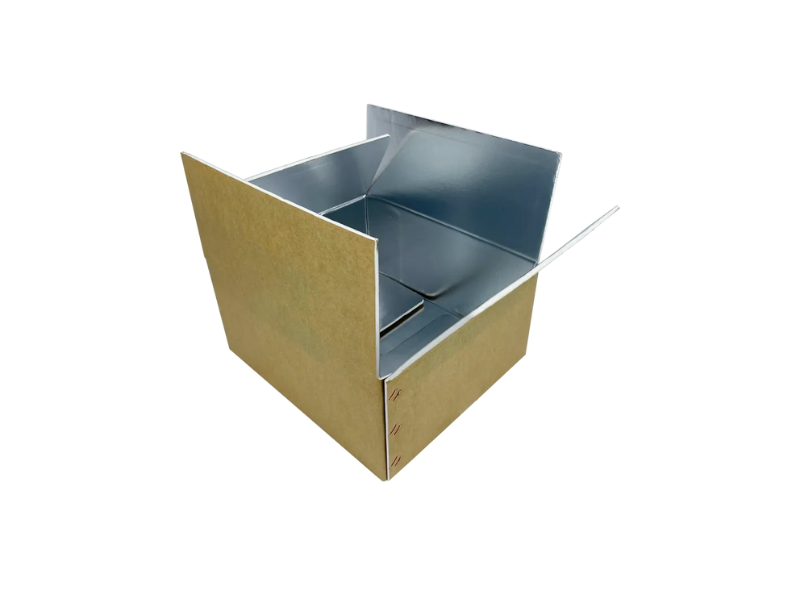

Let us first consider the construction. A sheet of foam that is dropped into a corrugated mailer is going to leave a lot of seams and gaps, which are going to be thermal bridges that allow a lot of heat to enter the container. More advanced boxes will use laminated or molded construction, in which the insulation is the fused between high-strength inner and outer liners. This monocoque design has no weak points. The closure mechanism is also important. A weak closure is a significant weak point. Designing a closure that can interlock, such as lined and grooved seals or a heavy-duty latching system, creates a long pathway for heat to travel and is a good way to keep the cold environment stored.

Secondly, the use of Phase Change Materials is revolutionary for 48-hour holds. They are technically not insulation but rather temperature regulators. They usually come in the form of gel packs or panels that are preconditioned to be frozen at specific temperatures. They are placed inside the box, and as the outside heat tries to get in, the system will absorb the energy and gradually shift from solid to liquid, which will keep the inside temperature stable for a long time. The hold time is extended only if the correct amount of PCM and phase temperature is calculated to make it work like a rechargeable thermal battery. This makes it so passive insulation doesn't even begin to hold stable temperatures as long as PCM can.

Customized Solutions Just For You

No solution fits all, and no solution can be called the best. Finding the right fit is a process of finely adjusting the solution to fit the details of a given product, a route, and a season. Therefore, buying a standard box should be shifted to engineering a thermal assurance package.

The process starts with a thermal profile of the product. What is its temperature tolerance? Is it frozen, chilled (2-8°C) or cool (15-20°C)? How much thermal mass does a typical shipment contain? A box of frozen berries has a lot of thermal mass, while a few vials of medicine have very little. How a product tolerates temperature change determines how stable the internal environment has to be.

Next, map the environmental journey. What is the worst-case external temperature it will face—peak summer heat or winter freeze? What is the total transit timeframe, including potential delays at sorting hubs, or on the delivery truck? Understanding these "thermal challenges" allows for intelligent design. For instance, a Cold Chain Box destined for summer delivery of high-value seafood might combine VIP walls with a calculated mass of PCMs. A subscription meal kit service shipping in milder climates might find a robust PU foam box with strategically placed gel packs to be perfectly adequate and cost-effective.

Specialist manufacturers in the industry are BoxPack. With over twenty years in the controlled temperature packaging industry, the company understands the full consulting value. A packaging supplier does not just sell boxes. BoxPack does the groundwork to find solutions for the customer. BoxPack understands the factors that customers often overlook, including the required structural integrity for a distribution model, marketing potential from a branded box, and the use of environmentally responsible materials, including FSC certified papers, RoHS-compliant inks, etc. BoxPack aims to deliver total packaging solutions with confidence to preserve freshness, integrity, and trust for every order.