How to Customize Cold Shipping Boxes for Fresh Meat Transportation?

The Importance of Custom Meat Shipping Solutions

Transporting meat is no ordinary delivery job. It's an exercise in logistics involving safety, perishability, and reputation. Meat products are among the most difficult items to ship, as they require special handling and transport. They are temperature-sensitive, pose health risks if mishandled, and are generally most susceptible to deterioration.

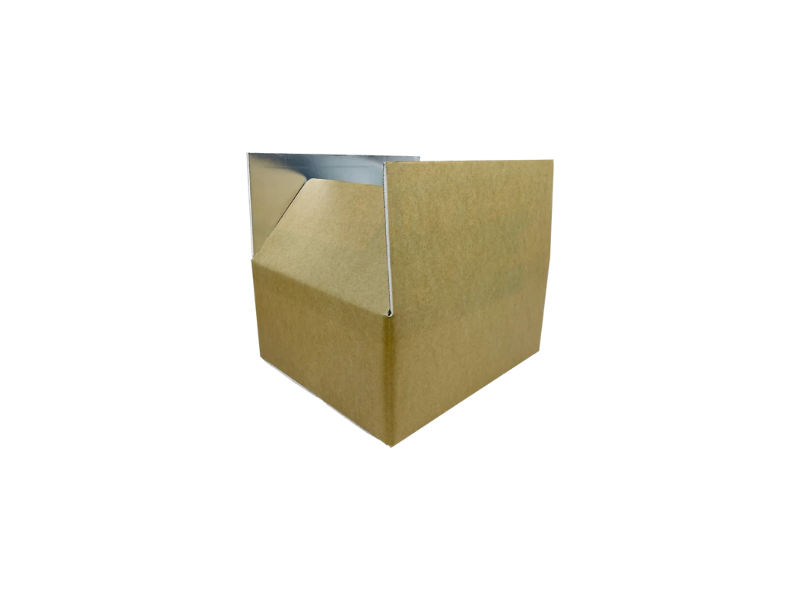

Generic shipping boxes won't work. They cannot support the 'hockey puck' level of cold that's needed for meat, nor are they set up for meat shipping's unique leaks, drips, and moisture challenges. That's why all the risks associated with shipping meat require specialized shipping meat boxes. Custom meat shipping containers are purpose-built to provide a reliable traveling environment for the meat, and keep it cold from the processing plant to the customer. For online butchers, meat subscription meal kits, and meat delivery services, the right shipping solution is the first and essential step to establishing customer confidence and delivering a great shipping experience.

Choosing Suitable Materials and Insulation

The key to an effective meat shipping solution begins with the materials being used. The box should withstand both thermal transfer and structural failure. For the outer housing, double and triple wall corrugated cardboard is a fantastic starting point because of the strength to weight ratio. However, for a truly good Cold Shipping Boxes, a lot of builders bolster this with a moisture resistant laminate. This laminate is important because it keeps the cardboard from degrading when it gets wet from the meltwater of the ice or gel packs. This keeps the box from losing structural integrity for the duration of the trip.

Although most people won't think of them, the insulating layer of a live animal shipment container is just as, if not more important than, the thermal performance of the container. For live animal shipments that require a 24-48 hour transit time, food-grade expanded polystyrene (EPS) or polyurethane (PU) foam liners are preferred. EPS is less expensive while providing the same quality of insulation as PU, but PU usually has a higher R-value per inch (insulating value) meaning the container can have slightly thinner insulating walls.

The insulation is between 1 to 3 inches thick, and the thickness is determined based on expected transit times and the outside temperatures. For higher quality longer distance shipments, lighter insulating vacuum panels (VIPs) are available. The tools available to a shipper and the materials with insulating properties is a thoughtful combination of insulation efficiency, transit container weight, and insulation material cost. The insulation is designed with a specific logistics pathway in mind.

Temperature Management Engineering and Moisture Control

Passive defenses include things like insulation. However, controlling a temperature actively requires a designed cold chain strategy to be a part of the box's structure. Keeping temperature cold is the this cold source. For example, the gel packs, dry ice, or phase change materials (PCMs) that absorb heat.

A custom made box is more than just being a hollow shell; it is designed with specific placement of cold sources in mind. Dividers or molded foam inserts can be designed to hold gel packs tightly up to the top and side walls to ensure they make full thermal contact and to stop shifting and crushing the product. Some designs include compartments specifically made for for dry ice with ventilation for sublimation.

At the same time, moisture management is crucial. Melt water from gel packs and the natural meat juices (in case of a leak) need to be managed. A good, custom solution should ideally come with an integrated, leak-proof liner or bag. This could be a sealed, food-grade polyethylene bag within the box or an interior coating that is foil lined. Also, the box design should provide for adequate drainage or absorption if used with wet ice, but for most shipments with gel packs, total containment is the aim. The focus on climate control within the micro-environment of the box is what enables the meat to stay within the ideal temperature zone for an extended period.

Designing for Product Security and Customer Experience

This last step of the design process involves customization of the practical aspects of the product. As meat is quite dense and heavy, the box and the inner packaging need to be designed to immobilize the product for the entire length of the journey. Custom die-cut foam inserts or corrugated cardboard dividers can be designed to snugly cradle the individual cuts, steaks, or whole roasts to prevent movement and sustain air network around the product for continuous cold airflow. Preventing movement will also avoid bruising and other physical damages.

The opening of the package is the first moment of interaction with the brand, for it is not pure functionality, it is also a matter of moment marketing. If the box is a plain, white box, you have a lost marketing opportunity. There is a lot of opportunity to customize the thermal box to include your brand's logo, shipping instructions, caring instructions, cooking tips, etc. With their packaging, customers communicate immediately the quality, the consistency, the professionalism of a brand by using bold, simple, and clean graphics.

A box designed with easy open tabs, cold packs, and clear waste disposal instructions also adds a lot of customer service. The impressions of a brand is also shaped by packaging. Having a designed, clean, and well constructed Cold Shipping Boxes that the customer is able to see is structured to order and served as a top notch cooling box, the customer is able to see their order through the box. The first impression of a delivery is packaging structured also communicates a lot about the quality of a brand.

It should have been a simple delivery, however, it is a high quality delivery structured by a box. A customer also should have received a box, however, a cold box was neccessarily structured to allow the meat to not spoil during shipping. A cold box is a logistics and packaging engineering high quality delivery. When the meat is not spoiled and is served along with quality packaging and structured in a high quality box, the brand will receive repeat business and positive feedback. The packaging engineering company structured the packaging with thermal science, structured engineering, and marketing branding, without them, it is complex. It is the company to achieve the goal of packaging logistics for the meat delivery.